2017 Hyundai Elantra Ignition Coil Performance Highlights

Consistent Spark Output: Maintains stable ignition across all RPM ranges and temperature extremes, ensuring smooth engine starts and responsive performance.

Premium Copper Windings: Enhances conductivity and reduces power loss, delivering efficient energy transfer directly to the spark plug.

Reinforced Epoxy Housing: Protects internal components from heat, moisture, and vibration—ideal for both city driving and long-distance operation.

OEM Level Compatibility: Direct-fit replacement for OE 273013C000 with secure left-side latch design, enabling seamless integration into coil-on-plug systems.

Wide Application: Compatible with numerous Hyundai and Kia models featuring 2.0L to 3.8L G-series engines, including Genesis, Sonata, Santa Fe, K9, and Sorento.

High Reliability Under Pressure: Performs dependably under high cylinder pressure conditions, ensuring stable spark and consistent power delivery.

Supports Advanced Combustion Technologies: Ideal for engines using EGR and GDi technologies, contributing to cleaner combustion and improved fuel efficiency.

2017 Hyundai Elantra Ignition Coil Technical Specifications

| Specification | Description |

| Coil Type | Coil On Plug (COP) Ignition |

| Voltage | 12V DC (Nominal) |

| Peak Ignition Voltage | Up to 42,000 V |

| Spark Energy | 45 – 55 mJ (varies by operating condition) |

| Primary Resistance | 0.50 Ω |

| Secondary Resistance | 5,800 Ω |

| Turns Ratio (P:S) | Approx. 1:75 |

| Inductance | 2.2 – 4.0 mH |

| Voltage Rise Time | < 2.0 kV/µs |

| Operating Temperature | –40°C to +135°C |

| Storage Temperature | –40°C to +100°C |

| Fluids Resistance | Resistant to gasoline, motor oil, coolant, and transmission fluid |

| Vibration Resistance | Up to 50g |

| Housing Material | PPS composite with high-durability epoxy encapsulation |

| Mounting Type | Single Bolt Mount (Left-Side Clip Orientation) |

| Mounting Hardware Included | No |

| Mounting Hole Quantity | 1 |

| Connector Gender | Female |

| Terminal Gender | Male |

| Terminal Quantity | 3 |

| Terminal Type | Blade |

| Ignition Type | Standard |

| Oil Filled | No |

| External Resistor Required | No |

| Package Contents | Ignition Coil Unit, Instruction Sheet |

| Coil Wire Included | No |

| Dimensions (L×W×H) | Approx. 110mm × 45mm × 65mm (varies slightly by SKU) |

| Weight | Approx. 320g |

| Applicable Engine Types | 1.6L / 2.0L GDi Inline-4 (e.g., G4FC, G4NA) |

| Standard Compliance | ISO 9001 / IATF 16949 |

Compatible Vehicles for 2017 Hyundai Elantra Ignition Coil Replacement

| Make & Model | Platform | Year | Engine Displacement | Engine Code |

| Kia Cerato R | — | 2015–Present | 1.6L | G4ED |

| Kia Cerato (GL/GLS trims) | — | 2006–2012 | 1.6L | G4ED |

| Kia Cerato (GL/GLS trims) | — | 2008–2012 | 1.6L | G4ED |

| Kia Cerato (GL/GLS trims) | — | 2011–2015 | 1.6L | G4ED |

| Kia Cerato Euro | — | 2007–2016 | 1.6L | G4ED |

| Kia Rio | — | 2006–2010 | 1.6L | G4ED |

| Hyundai Accent | — | 2006–2011 | 1.6L | G4ED |

| Hyundai Elantra | — | 2006–Present | 1.6L | G4ED |

| Hyundai Elantra Sports | — | 2006–2016 | 1.6L | G4ED |

| Hyundai Elantra Yuedong | — | 2008–2009 | 1.6L | G4ED |

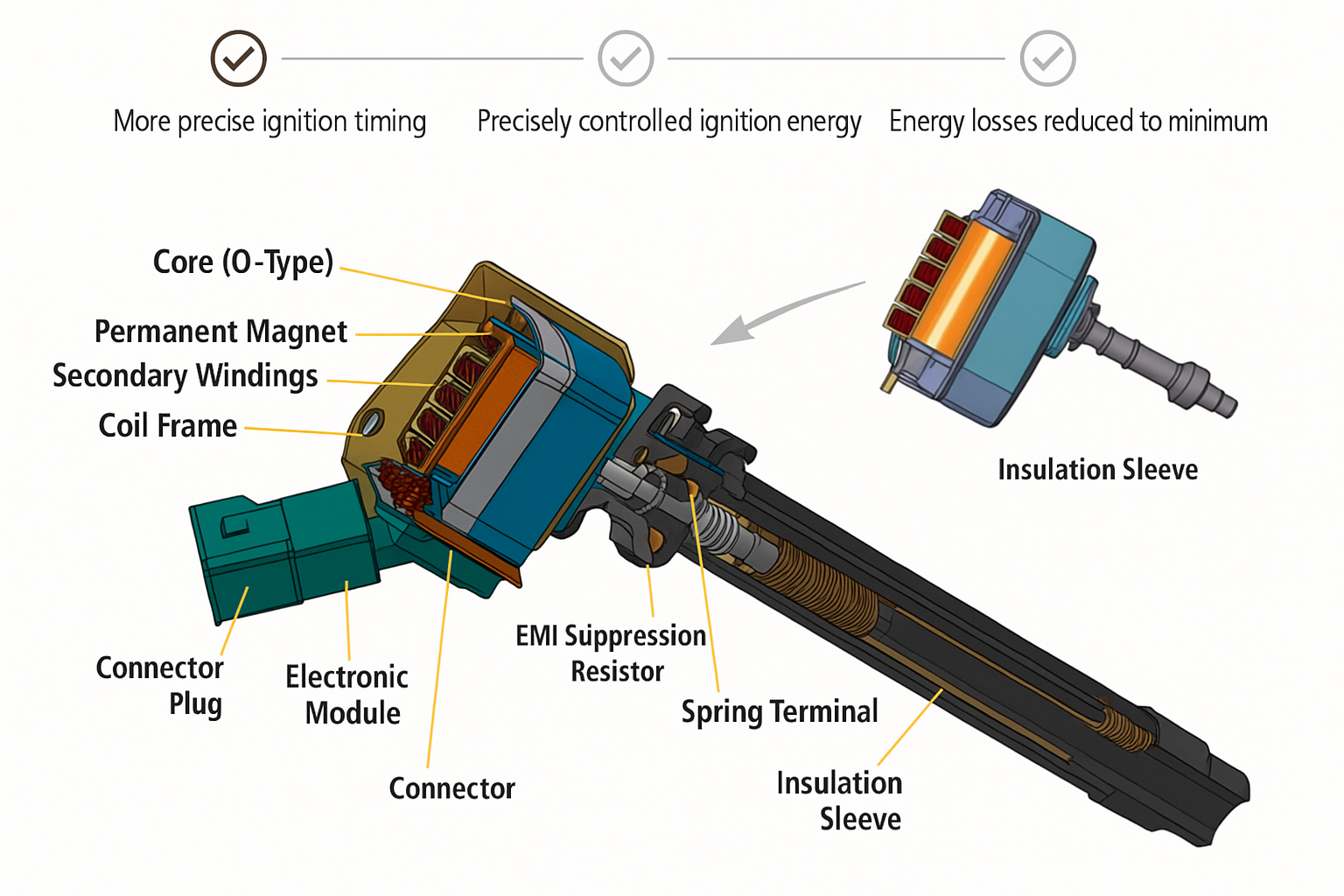

2017 Hyundai Elantra Ignition Coil Design & Component Overview

Understanding what goes inside a high-performance ignition coil reveals why Elecdurauto ignition coils deliver exceptional spark reliability, heat resistance, and long service life.

Every layer of Elecdurauto's ignition coil design is optimised for ignition precision, voltage control, and energy efficiency—especially in EGR (Exhaust Gas Recirculation) and lean-burn systems where fuel economy and CO₂ reduction are essential.

![Ignition coil structure diagram from professional ignition coil manufacturer]()

How Our 2017 Hyundai Elantra Ignition Coils Are Manufactured and Tested

At Elecdurauto, we know that a high-performance ignition coil starts with precision engineering and ends with uncompromising quality control. That's why we've heavily invested in state-of-the-art production equipment and rigorous testing systems to ensure every coil meets OEM-grade expectations reliably and consistently.

![automated ignition coil assembly line for OEM production]()

Automatic Assembly Machine

![ignition coil ECU functional testing equipment for quality control]()

ECU Testing Machine

![ignition coil plastic molding area in IATF 16949-certified factory]()

Injection Mould Area

![automated secondary winding machine for ignition coil copper wire]()

Secondary Winding Machine

![shell injection area for high-temp ignition coil housing manufacturing]()

Shell Injection Area

![vacuum casting system for ignition coil insulation and durability]()

Vacuum Casting Equipment

![professional ignition coil testing equipment for OEM compliance]()

Product Testing Equipment

![dedicated ignition coil tester for high-voltage performance check]()

Ignition Coil Tester

![climate test chamber for ignition coil thermal cycling validation]()

Climate Test Chamber

![thermal shock chamber for ignition coil reliability testing]()

Thermal Shock Chamber

![ignition coil production workshop with lean manufacturing process]()

Assembly Workshop

![full-function performance tester for automotive ignition coils]()

Comprehensive Performance Tester

OEM & Aftermarket Uses for 2017 Hyundai Elantra Ignition Coils

2017 Hyundai Elantra Ignition Coil Certifications & Industry Standards

![ISO 9001, ISO 14001, ISO 45001, IATF 16949 certified ignition coil manufacturer for OEM and aftermarket supply]()

Choosing a Reliable 2017 Hyundai Elantra Ignition Coil Supplier

At Elecdurauto, we specialise in manufacturing and supplying high-quality 2017 Hyundai Elantra ignition coil and a wide range of global vehicle platforms. Our OEM-grade replacement ignition coils are trusted by importers, wholesalers, and aftermarket brands across 30+ countries. Whether you're sourcing bulk ignition coil supply, private label products, or direct-fit aftermarket alternatives, Elecdurauto delivers value, reliability, and service.

1. Global-Grade Manufacturing Power

To maintain our position as a top ignition coil manufacturer, Elecdurauto operates with world-class machinery:

Vacuum Casting Equipment – For high-purity resin insulation and heat resistance

Automatic Winding Machines – Ensuring stable and high-speed coil winding

High-Voltage Testing Systems – Guaranteeing 100% product safety and performance

Injection Moulding Machines – For precise and durable component shaping

We also run a dedicated mould and injection workshop, which allows us to have faster lead times and tighter control over consistency.

2. Specialisation in Chevy Ignition Coil Technology

Elecdurauto specializes in high-performance ignition coil solutions engineered specifically for Hyundai applications, including the 2017 Hyundai Elantra. Designed with high-temperature copper windings, precision-wound cores, and PPS-reinforced housings, each coil ensures reliable spark delivery under thermal stress and high-RPM conditions. Whether paired with the G4FC or G4NA engine, this ignition coil guarantees OE-grade performance and long-term durability.

3. Brand-Equivalent Sourcing + OEM/ODM Development

Our production facilities overlap with Tier 1 OEM manufacturers of Denso, Bosch, Valeo, Delphi, and Magneti Marelli—allowing us to offer equivalent-quality ignition coils that match original performance.

We support OEM replacement ignition coils, branded label customisation, and custom SKU development tailored to your local market needs.

Want to highlight your branding? We support private label ignition coil production with your logo, packaging, and barcode-ready shipping.

4. End-to-End Quality Control

We manage the entire production cycle—from raw material inspection to final packaging—with rigorous checks at every stage:

FMEA-based defect prevention

Standardised & lean production systems

Process stability testing & 100% final inspection

This ensures lower defect rates, fewer returns, and longer product lifespans for your customers.

5. Flexible Supply & Fast Lead Times

Whether you need 100 pieces of ignition coils for the 2017 Hyundai Elantra or a container shipment of mixed SKUs, our system is built to adapt:

Low MOQ (100 units per SKU)

Rapid 2–5 day dispatch for stock coils

15–25 day lead time for OEM & custom orders

Amazon FBA / Mercado Libre packaging support

2017 Hyundai Elantra Ignition Coil FAQs

1. What is the Minimum Order Quantity (MOQ) for your ignition coils?

Our standard MOQ for ignition coil bulk orders is 100 units per SKU, ideal for auto parts wholesalers, regional distributors, and Amazon sellers. For new partners or trial orders, we support flexible MOQ policies—reach out for current support programs.

2. What are your lead times for production and delivery?

For in-stock ignition coil models, we offer 2–5 day dispatch. For customised packaging, private label coils, or large volume orders, standard lead times are customised packaging, private label coils, or large volume orders, standard 15–25 working days, depending on SKU and quantity.

3. Do you support OEM/ODM orders for ignition coils?

Yes, Elecdurauto specialises in OEM and ODM ignition coil manufacturing. We provide full support for private labelling, custom SKU packaging, barcoding (EAN/UPC), and customised ignition coil design for regional fitment needs.

4. What certifications do your ignition coils meet?

Our factory is certified to IATF 16949, ISO/TS 16949:2009, ISO 9001, ISO 14001, and OHSAS 18001. These certifications ensure strict quality management, environmental control, and safety compliance—a must for global B2B ignition coil distribution.

5. Can I get free samples to test quality before placing a bulk order?

Yes. For qualified B2B clients like auto part importers or e-commerce platform sellers, we offer free ignition coil samples (just pay shipping) so you can test product fit, quality, and performance.

6. Do you support Amazon or Mercado Libre fulfilment needs?

Absolutely. Elecdurauto provides barcode-ready packaging, inventory consolidation, and dropshipping options for online sellers. Our coils come in compact, FBA-optimised boxes with model number and branding printed.

7. What support do you offer for long-term B2B partners?

For ignition coil importers and resellers, we offer:

Regional exclusive agency support

Priority stock allocation

Co-branded marketing materials

Product training for auto workshops and retailers

After-sales assistance and warranty management

8. What is your quality assurance process for ignition coils?

Every ignition coil undergoes:

High-voltage stress testing

Resistance & insulation checks

Vibration and thermal cycle testing

Final 100% functional test before packaging

We maintain a <0.5% warranty claim rate across all global markets.

9. Which countries or regions do you currently supply?

Elecdurauto supplies ignition coils to Europe, South America, Southeast Asia, and the Middle East through both direct export and local distributor networks. We're actively expanding and open to onboarding new partners.

10. How do I determine if this ignition coil is compatible with my vehicle?

Each Elecdurauto ignition coil is engineered to match OEM standards, including precise fitment for the 2017 Hyundai Elantra 1.6L and 2.0L engines. To confirm compatibility, check for matching OE numbers such as 27301-3C000, and verify your engine code (e.g., G4FC, G4NA). You can also refer to our detailed application chart or send us your VIN for accurate confirmation.

11. What are the signs of a failing ignition coil?

Common symptoms include engine misfires, rough idle, difficulty starting, poor fuel economy, and a check engine light. If you're experiencing these issues, it may be time to replace your ignition coil.

12. Can I install this ignition coil myself, or do I need a mechanic?

Many ignition coils, especially coil-on-plug (COP) types, are designed for easy installation. If you're familiar with basic engine components and have the correct tools, you can perform a DIY replacement. Always refer to your vehicle service manual for torque specs and safety guidelines.

13. How long do Elecdurauto ignition coils typically last?

Our ignition coils are designed for long service life, often exceeding 100,000 kilometres (60,000+ miles) under normal operating conditions. We use advanced vacuum casting, epoxy resin insulation, and high-temperature wire winding to ensure heat resistance and durability.

14. What is the warranty policy on Elecdurauto ignition coils?

All Elecdurauto ignition coils come with an 18-month / 20,000 km limited warranty covering manufacturing defects. With a warranty return rate of less than 0.5%, our coils have proven long-term reliability in over 30+ countries.

15. Are these coils compatible with turbo or hybrid engines?

Elecdurauto ignition coils for the 2017 Hyundai Elantra are designed primarily for naturally aspirated gasoline engines like the 1.6L G4FC and 2.0L G4NA. For hybrid or turbocharged versions, please consult our OE catalog or contact us directly to ensure compatibility with your engine system.

16. What makes Elecdurauto different from other ignition coil manufacturers?

We combine global raw material sourcing, advanced automation (e.g., robotic winding, in-house injection), and full testing procedures, including high-voltage, insulation, and vibration testing. With a proven track record across OEM, fleet, and aftermarket clients reliability, performance, and fast lead times at scale.