Views: 0 Author: Elecdurauto Publish Time: 2025-07-24 Origin: Site

You're on a sourcing call with a potential new turbocharger supplier. They're quoting you an impressive peak boost number and a very tempting price per unit. But as a smart buyer, you know the most important questions aren't about the final numbers—they're about what's happening inside that housing to produce those numbers reliably, day after day.

I've seen too many importers and e-commerce brands get burned by focusing only on the "what" (peak boost) and ignoring the "how." They end up with a container of turbos that look great but lead to premature failures, costly warranty claims, and a damaged brand reputation. The key to avoiding this disaster is understanding the engineering choices behind the specs.

To truly vet a supplier, you need a fundamental grasp of how a turbocharger works—not as an engineer, but as a strategic buyer who knows exactly where to look for signs of quality or corner-cutting.

That's why I'm not just giving you a simple list of parts. I'm giving you a buyer's blueprint. In this guide, I will deconstruct the turbocharger into its critical systems and examine the 10 components that truly define its performance, reliability, and ultimate cost. For each component, I will explain:

Its specific function in simple terms.

What you, as a buyer, should focus on (e.g., materials, manufacturing methods).

The exact questions to ask a turbocharger supplier to reveal the true quality of their product.

By the end of this post, you will be able to look at any turbo spec sheet and see beyond the numbers. You will understand the difference between billet and cast compressor wheels, why turbine material matters, and how the bearing system can make or break your product's longevity. Let's get started.

Let's get one thing straight: boost pressure is just an outcome. It's the byproduct of a high-speed, high-temperature system working in perfect harmony.

A cheap unit from an unproven automotive turbocharger supplier might give you high boost—for a while. But only a high-performance turbocharger from a reliable manufacturer will deliver sustained results over years of use.

If you're in bulk turbocharger sourcing for B2B, this is where your margin lives or dies.

The difference lies entirely in component quality, process control, and real-world validation. Understand that, and you're halfway to becoming a smart, profitable aftermarket turbocharger buyer.

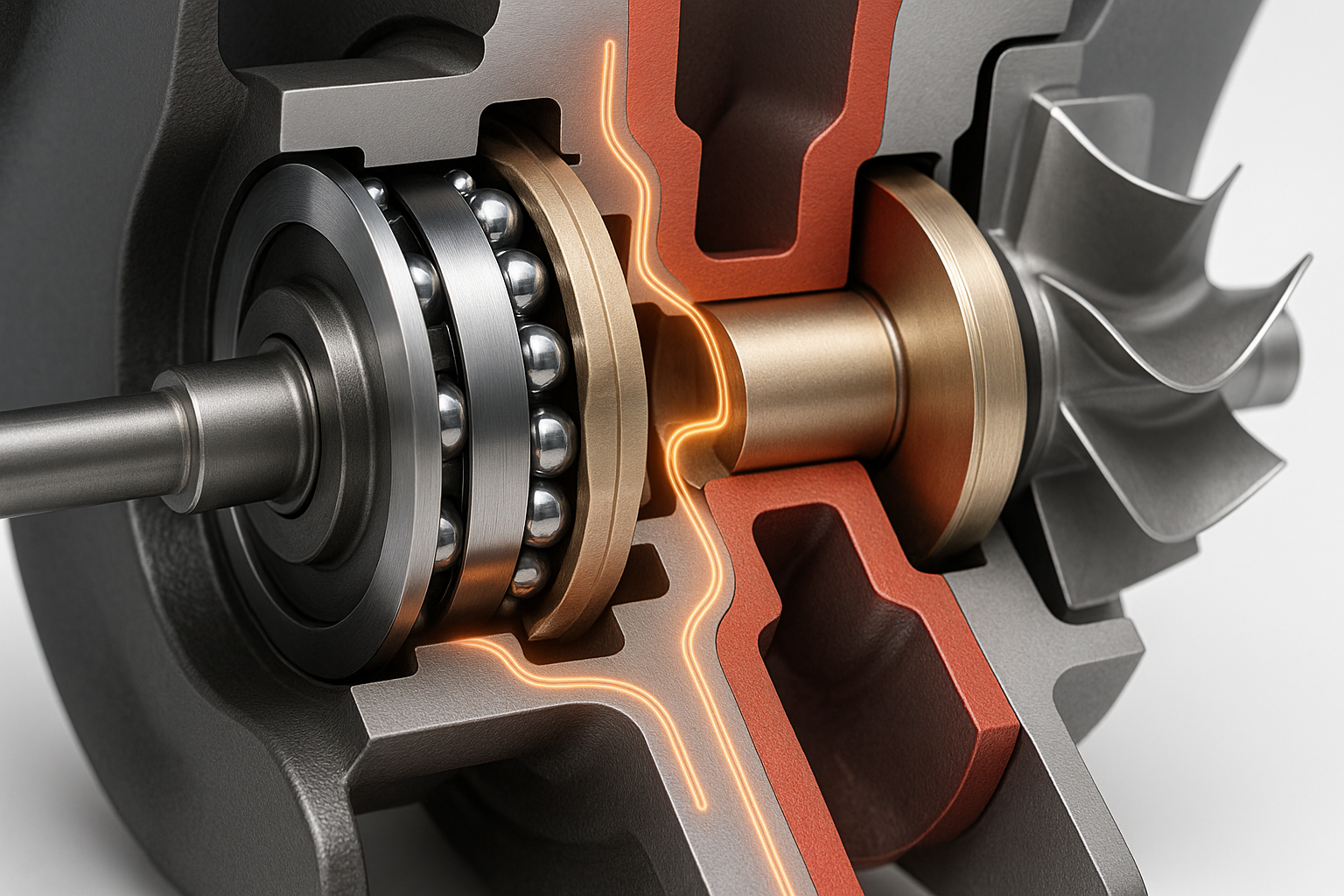

The Center Hub Rotating Assembly (CHRA) is the literal core of the turbocharger. It's where the magic happens, with components spinning at speeds exceeding 200,000 RPM. This is where quality matters most.

Think of the turbine wheel as a small, incredibly durable windmill. It sits in the stream of hot exhaust gas leaving the engine. This gas flow spins the turbine wheel, capturing waste energy that would otherwise be lost out the tailpipe. This rotational energy is the power source for the entire system.

To understand how a turbocharger works under extreme heat, you must look at the turbine material. I insist on high-nickel superalloys like Inconel 713C for any serious application because it maintains its strength at temperatures that would melt lesser alloys like K418. Also, pay attention to the "trim," which relates to the wheel's size and blade design. A larger trim can flow more gas for top-end power but may respond slower (more lag).

"What is the specific material of your turbine wheel—is it Inconel 713C or another alloy? Can you provide the spec sheet for it? Why did you select that particular aerodynamic trim for this application?"

This is the "cold side" counterpart to the turbine wheel. It's a high-tech fan that spins at the same incredible speed, sucking in fresh air and compressing it before forcing it into the engine. More air means more fuel can be burned, which means more power.

This is the classic Cast vs. Forged-Billet debate.

Cast wheels are cost-effective and perfectly reliable for most OEM-replacement applications.

Forged-Billet (or MFS - Machined From Solid) wheels are stronger, lighter, and can be machined into more aggressive, efficient aerodynamic shapes for higher performance. If a supplier is claiming premium performance, I expect to see a billet wheel.

A red flag for me is poor finishing on the blades of a cast wheel. It indicates a sloppy manufacturing process. Also, be wary of suppliers who can't explain the specific aerodynamic benefits of their billet wheel design.

This high-strength steel shaft connects the turbine and compressor wheels, transferring energy from the hot side to the cold side. It does this while enduring intense heat and torsional stress.

The shaft's material must resist fatigue. But the most critical process is balancing. A poorly balanced rotating assembly is a ticking time bomb. I don't just ask if it's balanced; I ask how. A proper, multi-stage balancing process is non-negotiable. First, the individual wheels are balanced, then the assembled CHRA is balanced again at operational speeds (VSR balancing).

"Can you describe your shaft balancing process? Do you perform VSR (Vibration Sorting Rig) balancing on the final CHRA, and what are your balance tolerances in G-levels?"

These components don't spin, but they are essential for directing airflow, containing pressure, and allowing the rotating assembly to survive.

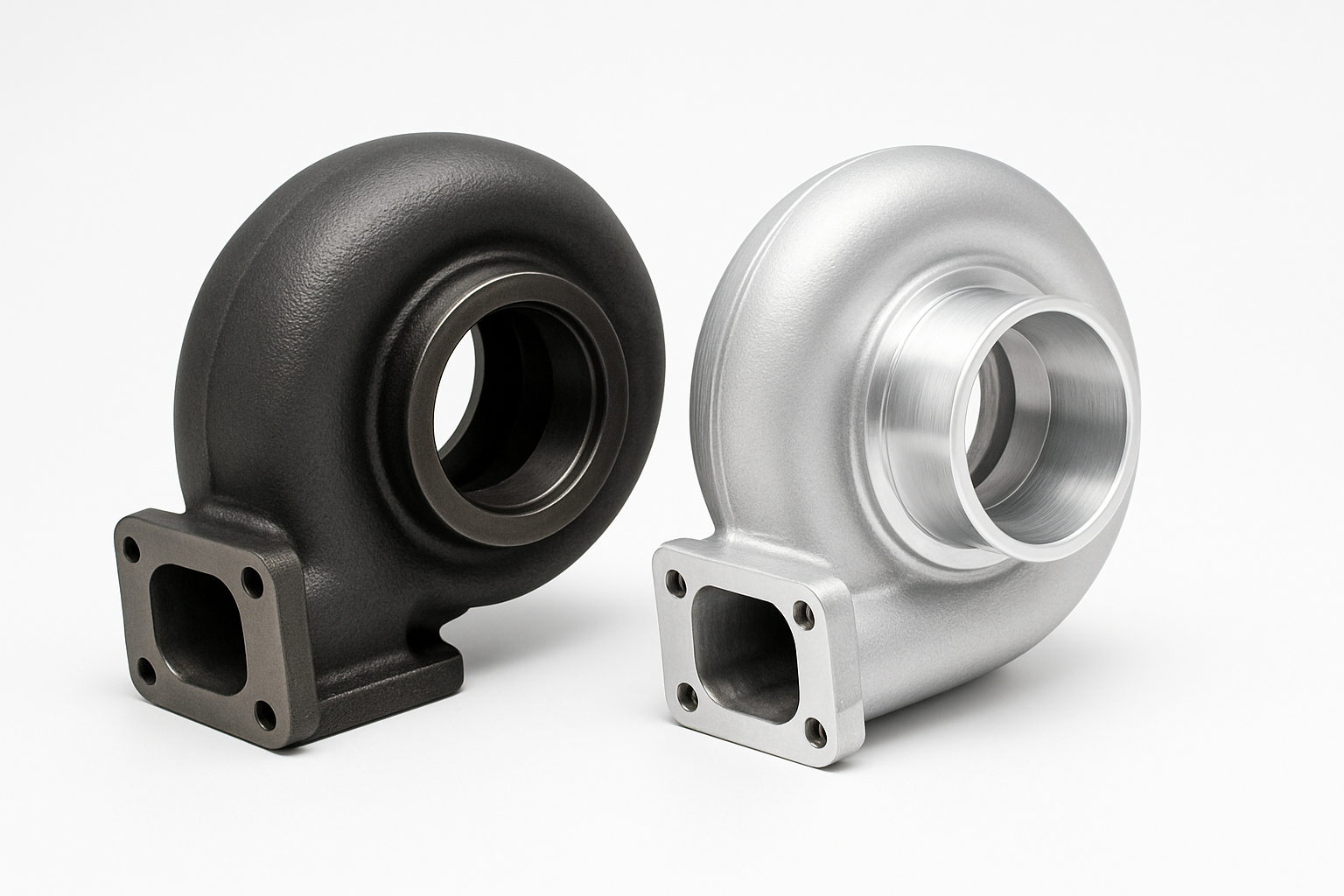

This is the snail-shaped shell on the "hot side." It collects exhaust gas from the engine and funnels it directly onto the turbine wheel blades.

The housing's A/R ratio (Area/Radius ratio) is a critical performance spec that dictates how the turbo responds. The material must be a high-quality, crack-resistant cast iron with high nickel content (like D5S) or, for premium applications, cast stainless steel to handle the extreme heat cycles.

"What is the nickel content and heat rating of your turbine housing cast iron? Do you offer different A/R options for this model?"

This is the "cold side" housing. It collects the pressurized air from the spinning compressor wheel and smoothly directs it out toward the engine's intercooler or intake.

A key feature on high-performance compressor housings is a "ported shroud" or "anti-surge" ring, which helps prevent compressor surge under certain conditions. The smoothness of the internal pathways is also critical for efficiency.

I always inspect the inside of the compressor housing. Any casting imperfections like pitting or rough surfaces can disrupt airflow, reduce efficiency, and signal poor quality control.

No part can spin at 200,000 RPM without a sophisticated bearing system. The shaft "floats" on a micro-thin layer of high-pressure engine oil supplied to these bearings. This is a common failure point and a huge differentiator between cheap and quality turbos.

Journal Bearings: The traditional, cost-effective standard. They are a "floating" bushing design and are perfectly durable when supplied with clean, high-pressure oil.

Ball Bearings: A premium option using ceramic ball bearings. They reduce friction, allowing the turbo to "spool up" (get to speed) faster. This is a key feature for high-performance applications and justifies a higher price.

"Is this a journal bearing or ball bearing system? What are your specified internal clearances for the bearings, and what type of 360-degree thrust bearing do you use to handle axial loads?"

These are the parts that control the turbo's power and keep the oil where it belongs. Failures here can be catastrophic.

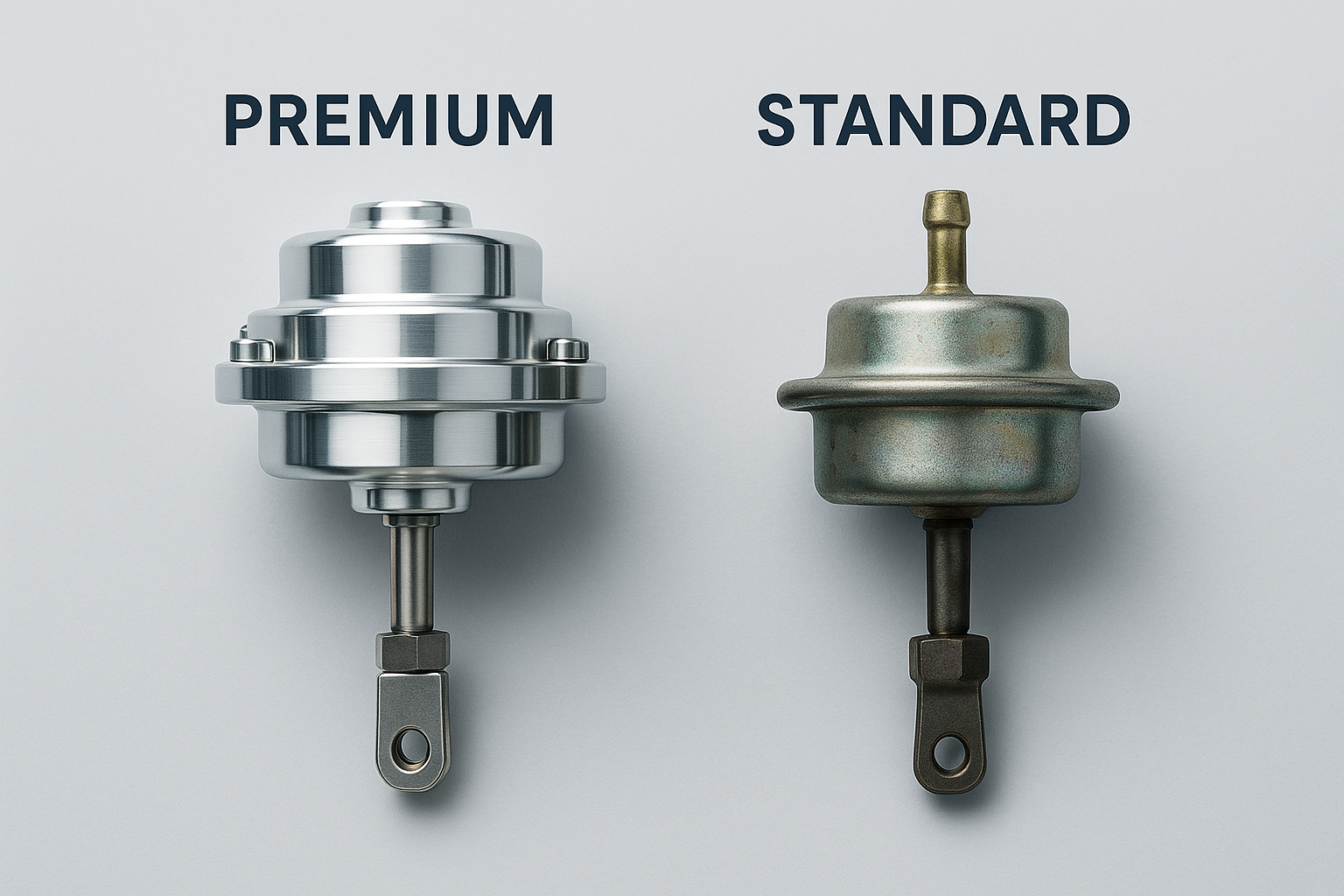

The Wastegate is a bypass valve on the hot side. It opens to divert some exhaust gas around the turbine wheel, which controls the turbo's speed and prevents it from over-boosting the engine.

Most turbos use an internal wastegate. The quality of the actuator that controls it is paramount. The actuator's diaphragm must be high-quality to resist heat and pressure, and the spring inside determines the base boost level.

"What material is your wastegate actuator diaphragm made from? What is its pressure and temperature rating?"

When you suddenly close the throttle on a boosted engine, the pressurized air has nowhere to go. The Blow-Off Valve (BOV) is a pressure relief valve on the cold side that vents this pressure, preventing a damaging surge back against the compressor wheel.

A quality BOV uses a durable metal piston (like aluminum) rather than plastic. The spring inside must have a consistent rate to open and close reliably without leaking boost.

For me, a plastic piston in a BOV intended for anything other than low-boost OEM replacement is a major red flag for durability.

These tiny, often-overlooked seals are the guardians of the CHRA. A special type of piston ring on the turbine shaft keeps high-pressure gas out of the bearing housing. Sophisticated oil seals keep engine oil inside the bearing housing.

This is a classic area for cost-cutting. A failed seal is what causes the dreaded blue smoke from the exhaust. I look for suppliers who use superior "step-gap" piston rings, which provide a much better seal than simple standard rings. The material of the oil seals must be rated for high temperatures.

When a supplier dismisses a question about their seal design or can't specify the material, it tells me they are likely using the cheapest available option.

As you can now see, how a turbocharger works is a story told by its components. It's a system of incredibly precise, high-stress parts that must function as a perfect team.

When you source a turbocharger, you are not just buying a peak boost number. You are buying a specific set of engineering decisions. You are buying Inconel or a cheaper alloy. You are buying a billet or a cast wheel. You are buying a precisely balanced assembly or a potential warranty nightmare.

By using the questions and focus points in this guide, you move from being a price-taker to a strategic partner. You signal to suppliers that you value quality and understand the engineering that creates it. This is how you build a turbocharger supply chain that delivers not just parts, but performance, reliability, and profit.