| Reference Category | Part Number / Keyword | Notes for Buyers |

| Aftermarket / Code | 6596 | Common service reference |

| OE Cross Reference | 1113272 | Useful for catalog alignment |

| Application | John Deere engines | Confirm by old unit photos when needed |

| Fitment Checks | 10T + wet clutch + terminals | Key checks to avoid install delays |

Inside Elecdurauto Starter Motor Supplier Factory & Advanced Equipment

At Elecdurauto, the components of each product are strictly inspected to ensure the quality of the products.

New series of products have to undertake all kinds of tests before out into SOP, such as DV performance test,environment test, electromagnetic vibration test, endurance treat.

![Electromagnetic Vibration Tester (On Working Condition)]()

Electromagnetic Vibration Tester (On Working Condition)

![Starter DV Performance Tester]()

Starter DV Performance Tester

![Starter Endurance Test Zone]()

Starter Endurance Test Zone

![Environment Test Area]()

Environment Test Area

How Elecdurauto Starter Motor Supplier Produces Each Unit

At Elecdurauto, every starter is manufactured to exacting standards through our fully integrated production process. From rigorously inspected raw materials to precision machining and automated assembly, each step is optimized for consistency and performance. Every unit undergoes dynamic testing to ensure unmatched reliability—meeting the demands of both OEM specifications and aftermarket requirements.

![Starter Raw Materials Preparation]()

Starter Raw Materials Preparation

![Starter Component Processing]()

Starter Component Processing

![Starter Parts Fabrication]()

Starter Parts Fabrication

![Starter Parts Assembly Process]()

Starter Parts Assembly Process

![Starter Automated Production Line]()

Starter Automated Production Line

![Starter Quality Control Check]()

Starter Quality Control Check

![Starter Final Product Assembly]()

Starter Final Product Assembly

![Starter Finished Goods Storage]()

Starter Finished Goods Storage

Quality-Certified Starter Motor Supplier for Global OEM and Distributor Markets![]()

With extensive experience in supplying to OEMs and large distributors, Elecdurauto understands what global compliance truly means. Our starter motors can be tailored to meet the required certifications and regulatory standards in your region — whether it's CE for Europe, E-Mark for automotive electronics, INMETRO for Brazil, or GCC conformity for the Middle East.

What We Offer:

ISO/IATF 16949 Certified Production

ISO 14001 Environmental & Safety Compliance

Optional CE, RoHS, E-Mark, REACH, INMETRO & others

Lab testing partnerships for electromagnetic compatibility (EMC), durability, noise & vibration, and more

Customized labeling and documentation to meet your import/export requirements

Trusted by Leading Markets:

From Latin America to Europe, from Southeast Asia to the Middle East, Elecdurauto has helped partners streamline entry into demanding markets with localized solutions and on-demand compliance support. We've done it before — and we're ready to do it for you.

OEM Project Case from Elecdurauto Starter Motor Supplier for Global Brands

At Elecdurauto, we take pride in delivering more than just starters—we provide end-to-end solutions tailored to our clients' exact needs. As a trusted OEM supplier for starters, we've built long-term partnerships by combining precision engineering, responsive service, and value-added support.

From initial design collaboration to final delivery, we ensure every starter meets strict OEM specifications while optimizing for performance and durability. Our team works closely with clients to refine packaging, streamline logistics, and even assist with product development—ensuring a seamless integration into their production lines.

![Starter Motor Samples]()

Starter Motor Samples

![Designed Boxes with Client Logo]()

Designed Boxes with Client Logo

![Client Showcasing]()

Client Showcasing

![OEM Starter Models Showroom]()

OEM Starter Models Showroom

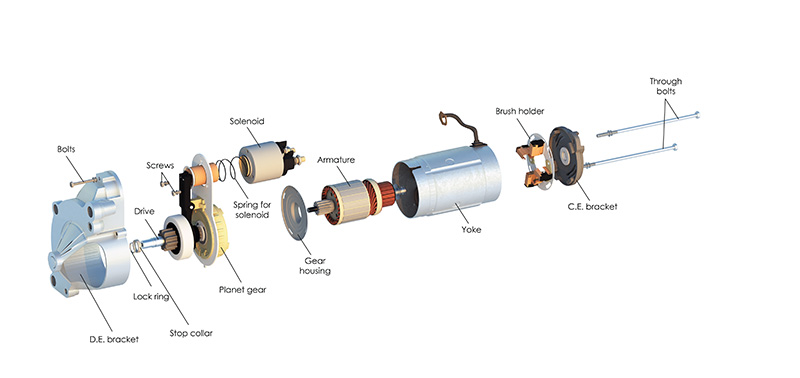

![Detailed Shot of Starter Motor]()

Detailed Shot of Starter Motor

![Precision Components Inside Starter]()

Precision Components Inside Starter

![Surface Texture and Labeling on Starter]()

Surface Texture and Labeling on Starter

![Starter Motor Units Before Packaging]()

Starter Motor Units Before Packaging

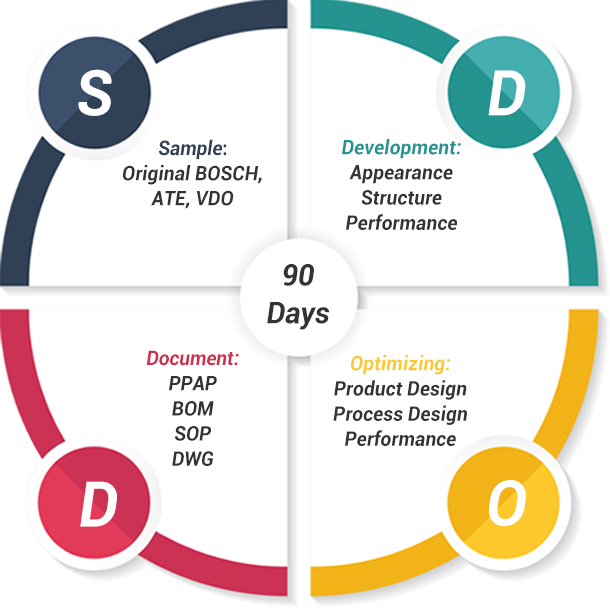

Elecdurauto Starter Motor Supplier OEM Development Process

![]()

Your Reliable Parter for Starter Motor Supply

Elecdurauto brings together a powerful network of China's top automotive electrical component manufacturers to serve global buyers with unmatched efficiency.

As your strategic sourcing partner, we offer:

Competitive factory pricing

Product quality on par with international brands

Full support across fuel and new energy vehicle segments

From OE-compatible starter motors to custom-developed units, Elecdurauto empowers wholesalers, distributors, and OEM customers with reliable supply chain access and flexible production capability.

![]()

Why Industry Leaders Choose Elecdurauto

R&D Strength – From Fuel to EV

National-level high-tech enterprise focused on motor system innovation

¥300M+ R&D investment spanning ICE, BEV, HEV, REEV platforms

Advanced Manufacturing Capability

Modern production centers certified to GMW Global & CINA standards

Full-process automation with real-time quality control, smart warehousing, and digital visualization

Industry-leading single-line output capacity

Precision Process Engineering

Built upon Six Sigma and lean production principles

Smart upgrade from traditional to digitalized manufacturing

Capable of complex processes: round wire stators, high-density alternators, IPX4/IP67 protection-grade starters

Comprehensive Quality Assurance

Full IATF 16949, ISO 14001 compliance

In-house testing: performance, NVH, life-cycle (except EMC)

Certified by top OEMs: GMW, Chery, JAC, Foton, Caterpillar

Lifecycle validation: 45,000 to 350,000 cycles for start-stop systems

High Capacity & Product Range

Starter motor digital assembly line: 2 million units/year

Rotor production: 3 million units/year

Flat wire stators/rotors: 250,000 units/year

Round wire motors: 240,000 units/year

Starter assembly total capacity: 600,000 units/year

Frequently Asked Questions – 6596 28MT 24V 4kW 10-Tooth Wet Clutch Starter Motor Manufacturer

1. What makes the 6596 28MT 24V wet clutch starter motor different from 6598?

Both can be 10T 24V types, but 6596 uses a wet clutch sealed drive and commonly a 4-terminal solenoid, while 6598 is commonly dry clutch and 3-terminal. Drive style and terminals are key differences.

2. Why choose a 6596 wet clutch 28MT starter motor instead of a dry clutch version?

Wet clutch sealed drive helps in layouts where oil exposure or contamination near the starter nose is common. It can reduce drive wear and sticking problems over time.

3. Why is 32 mm pinion OD important on the 6596 10T starter motor?

It helps confirm correct drive geometry. A 10T starter with 40 mm OD may not mesh correctly and can cause grinding or noisy starts.

4. What does 82.5 mm engagement mean on a 6596 starter motor?

It indicates pinion travel depth. Incorrect engagement can cause partial meshing and ring gear damage—especially under heavy cranking loads.

5. Why does a 6596 24V starter motor use a 4-terminal solenoid?

Some harnesses require the extra terminal for control logic. If the old unit was 4-terminal, substituting a 3-terminal can create no-crank or wiring changes.

6. Why does a 6596 wet clutch starter motor click but not crank?

Often electrical: weak batteries, voltage drop, or corroded grounds. Confirm voltage at the starter under crank before replacing the unit.

7. How do coastal environments affect a 6596 28MT wet clutch starter motor?

Coastal corrosion increases resistance at terminals and grounds. Wet clutch helps drive sealing, but wiring still needs corrosion protection.

8. How do cold climates affect a 6596 24V starter motor?

Cold increases engine load and reduces battery output. Balanced batteries and clean grounds are essential to avoid slow cranking complaints.

9. What symptom suggests the customer ordered the wrong 10T wet clutch starter?

Grinding on start-up, incomplete engagement, or unusual noise often indicates OD/engagement mismatch or wrong mount alignment.

10. What is the fastest way to confirm a 6596 starter motor replacement?

Confirm 6596 reference, verify wet clutch sealed drive, and match 10T + 32 mm OD + 82.5 mm engagement + 4 terminals using photos.